Table of Contents

Lulzbot Taz4

3D Drucker der derzeit im Raum ist und super cool und verwendbar: Lulzbot TAZ4

Manual

Pre-Print Checks

- Is the printbed level?

- If not –> Printbed Leveling

- Is the surface clean?

- If not –> Clean with alcohol/spirit/glass cleaner

- Is the filament dustfree? If not –> Clean with pressured air.

- Make sure dust does NOT get into the extruder.

- Print and deploy a Filament Cleaner if not present

- Is the filmanet entangled? –> disentangle.

- Load correct material profile in Cura.

- If in doubt use “Fast” –> see Materials

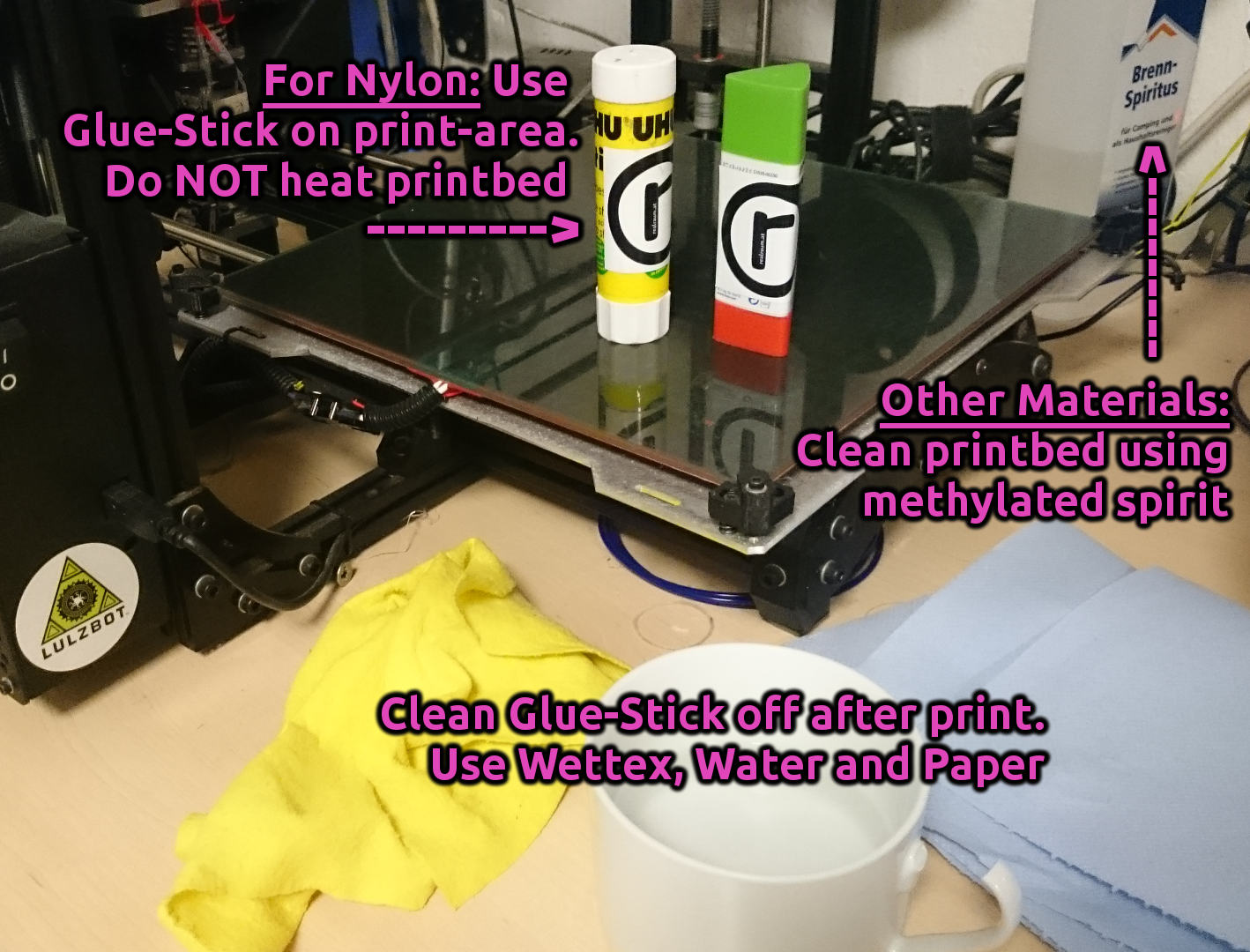

- Are you printing Nylon?

- Prep with Glue Stick. Clean/Remove with Water afterwards.

- Need to change filament?

- Check for difference in extrusion temperature and follow guide

monthly Maintenance

Lulzbot: Maintaing your 3D printer

- Verify that both Z-rods turn equally smoohtly. Test by first disconnecting motors. Check left/front Z-axis-leadscrew is exactly 90* to rod. If off by 0.1°, then that Z-rod turns less well. Loosen screws.

- Verify that X-axis sledge is level, aka Z-distance on both rods is identical to Z-axis-motors

- Verify that there is no tension between Z-axis rods. (i.e. because X-rods have been fixed too tight. Don't need to be fixed at all, can remain loose.

- Check belt tension.

- a bit loose is just right

- Wipe down smooth rods with clean cloth.

- Lightly lubricate and clean the threaded rods with silicone based grease. DO NOT use oil or spray. (ask xro for teflon grease)

- Use compressed air to blow out the fan/control box while powered down.

- Verify that any frame and motor screws are tight.

Tipps and Caveats

Jemand hat Ocotoprint installiert und den Lulzbot unter http://3d-lulzbot.realraum.at/ erreichbar gemacht.

Guide to Obtaining Great Prints

Printbed Leveling

Basic Procedure:

- Home Z Axis

- Make sure extruder does NOT touch print surface

- Adjust corner spring screw or z-axis endstop until a piece of 80g paper slides just between extruder and print surface

- Leave Paper on print surface while moving extruder to protect surface and see when print-head touches/moves paper

- Move extruder to all four courners. Adjust corner spring screws accordingly

- Repeat a second time

- Move extruder to center and check again. Our Printbed is probably slightly curved so make sure the extruder DOES NOT touch the printing surface in the center.

Changing Filaments

Use Cleaning Filament when changing to a filament with a different extrusion temperature.

Otherwise lower-temp filament will charcoal inside the hotend at higher temperatures which can obsctruct the hot-end and create back-pressure and can be almost impossible to clean out.

- Heat to temperature of current filament

- Cut filament cleanly near extruder

- Pull out rest of filament

- Insert cleaning filament until only cleaning filament comes out of extruder

- Lower/Raise temperature to new filament temperature

- Insert new filament until no more cleaning filament comes out of extruder

- Fixate new filament, don't tighten screws too much, just use enough force so that extruder has grip on filament.

Heatbed too cold

Does it affect your print? If not, don't worry about it. Otherwise see below.

On cold days the heatbed glass can lag about 10min behind the heatbed temperature. Close the window curtain to reduce ambient heat loss. Preheating the bed for a longer time before starting the print may help. If the heatbed continously does not reach target temperature, use the materials in MaSha to build an enclosure for the TAZ.

Filament gets stuck, print stops

There is an edge inside the extruder in the filament shaft between the metal and plastic part. It can't be fixed, but the filament can be inserted in a way that the natural curl of the filament keeps the filament from getting stuck on that edge.

Use the PTFE tube to guide the filament into the extruder from the backside (display is front-side) of the printer.

We observed Stainless-Steel PLA to be wobbly on some places on the spool. The wobbles will make the filament get stuck in the PTFE tube. Try without the tube. Watch the print and make sure filament does not get stuck.

Some parts of my design is not being printed

- Check your model in the layer view of Cura.

- Wall thickness should be a multiple of the nozzle size.

- Try a finer profile.

Extruder or other stepper overheats and stops working

This happened once, because the current regulation on the controller board was shot. Read the blog. Order new board and replace it.

Model Design

You wall thickness should be a multiple of the nozzle size.

If you are printing thing walls for cookie cutters, make sure your wall is thick enough to be printed. You can check in cura in the layers-view.

Changing the Nozzle

Current Nozzle Size is 0.5 (self-drilled). It's fast and accurate. Don't change it if in doubt.

We also have a 0.35 Nozzle. You will only need it for very fine prints.

Warning beware of youtube videos that show nozzle change at room temperature. read Lulzbot Errata

Procedure:

- Heat extruder to 160°C.

- Removing the nozzle with the hot end cold, with the presence of plastic on the threads can potentially damage the nozzle threads/threaded extension

- Unscrew the nozzle.

- Hold the extruder with a second wrench.

- Don't damage the wires or heating element.

- Don't touch bare wires with metal.

- Don't rotate the extruder.

- Install new nozzle

- thread the new nozzle slightly onto the threaded extension for only one thread

- Set the hot end temperature to 160◦C. Once the hot end has reached 160◦C finish installing the nozzle.

- Take extreme caution when handling the hot end when at high temperatures. Use leather gloves.

Materials

Correct profiles for each material can be found in: ~/lulzbot/cura profiles for TAZ4/ on Würfel or on Github

Fast Profile is alsmost always the right choice, unless you intend to print small models with very fine structures.

Nozzle Size is 0.5. If you change to the 0.35 nozzle, change it back before you leave the printer.

Use Cleaning Filament when changing to a filament with a different extrusion temperature.

Otherwise lower-temp filament will charcoal inside the hotend at higher temperatures which can obsctruct the hot-end and create back-pressure and can be almost impossible to clean out.

Printing with nGen

no special knowledge or care required

Printing with HIPS/PLA/ABS

Hips, PLA and ABS like to warp to various degrees during the print due to cooling/heating expansion. Keep print at uniform temperature. i.e. encase printer.

Printing with Nylon

Nylon does not stick to the print-bed. Not even with the heat turned on.

- Use Glue-Stick on printbed beforehand. Glue-Stick is in black LulzBot Bag, Please store there again after use.

Do NOT heat the printbed. That just leads to the Glue drying out early and the print failing.

you can heat the printbed normally. With the new PET surface, Bridge Nylon steaks really well on a heated and glued printbed.- Glue-Stick-glue is water-solvable. Clean printbed by putting wet paper or wet wettex on it, let it soak a minute and whipe off with paper afterwards!. Repeat several times until print-bed completely clean.

Nylon should regularly dried at 80°C for 7 Hours and stored in airtight container with desiccant. (Under the Table)

Printing with Stainless Steel PLA

Stainless Steel PLA sticks REALLY well to the PET surface. Don't use glue.

When the print is finished, wait for the pad cools and then VERY carefully try not to damage the print surface!

what materials can be printed ?

Everything with a filament diameter of 2.85mm-3mm (no less and no more) and extrusion temperature below 238°C that does not clog the nozzle , like wood-,stainless-steel-,conducitve,“magnetic”-filament does.

can it print 1.75mm filament

SORRY NO

Specs and Settings

| Specs TAZ 4.1 – Test Acceptance Record | |

|---|---|

| max build Area | 298mm x 275mm x 250mm |

| Resolution: | >=0.1mm |

| max Heatbed Temp | 120°C |

| max build speed | 200mm/s |

| Firmware | Marlin 2014-Q3 |

| Electronics | RAMBo 1.3L |

| Serial# | KT-PR0016-7986 |

| steps/mm X | 100.5 |

| steps/mm Y | 100.5 |

| steps/mm Z | 400 |

| steps/mm E0 | 842 |

Nozzle

| currently mounted Nozzle | |

|---|---|

| Diameter | 0.5mm |

| Max Temperature | 240°C (exceed at risk of DAMAGE) |

| Type | Budaschnozzle 2.0c |

Known Problems

- Metal Platform holding print-bed is bent at all corners

- this makes leveling harder, as the bending angle is different in all four corners

- this means that the Z-offset (screw below Z-Endstop on controller-side) needs to be set lower that it originally was

- this means, when z-leveling, the extruder-header goes lower than it was designed for and sometimes makes hurtful noises

- Folien gehört getauscht

- muss aufgeheizt werden auf 60°C bevor neue Folien aufgeklebt wird, sonst bilden sich blasen

Current Firmware Settings

2015-11-12

| Value | Setting from LCD |

|---|---|

| Autotemp | Off |

| Autotemp Min | 210 |

| Autotemp Max | 250 |

| Autotemp Fact | 0.10 |

| PID-P | 6.00 |

| PID-I | 0.30 |

| PID-D | 125.00 |

| PID-C | 1 |

| Zoffset | 0 |

| Accel | 500 |

| Vxy-jerk | 8 |

| vz-jerk | 0.40 |

| ve-jerk | 10 |

| vmax x | 800 |

| vmax y | 800 |

| vmax z | 8 |

| vmax e | 50 |

| amax x | 9000 |

| amax y | 9000 |

| amax z | 100 |

| amax e | 10000 |

| a-retract | 3000 |

| xsteps/mm | 100.50 |

| ysteps/mm | 100.50 |

| zsteps/mm | 1600 |

| Esteps/mm | 842.0 |

| E1steps/mm | 800.00 |

HeatBed Autotune

2015-11-12

- txt

bias: 41 d: 41 min: 64.86 max: 65.28 Ku: 250.58 Tu: 18.09 Clasic PID Kp: 150.35 Ki: 16.62 Kd: 339.93 PID Autotune finished! Put the Kp, Ki and Kd constants into Configuration.h

2017-09-15

- txt

bias: 77 d: 77 min: 79.66 max: 80.36 Ku: 276.82 Tu: 19.92 Clasic PID Kp: 166.09 Ki: 16.67 Kd: 413.63 PID Autotune finished! Put the Kp, Ki and Kd constants into Configuration.h

2017-09-15 Settings used for quick print start (less differential swing compensation so firmware >= startcheck succeeds)

- txt

M304 P166.0 I16.65 D390 M500